Perché scegliere SHINE SOON

La nostra produzione interna consente di fare tutto sotto lo stesso tetto, e i team possono rispondere direttamente alle tue esigenze. In questo modo, ciò che ottieni dalla fabbrica è ciò che i tuoi clienti riceveranno in una scatola.

Opzioni di soluzione di personalizzazione onnicomprensive

Situato nello Zhejiang, il rinomato centro di eccellenza manifatturiera in Cina, offriamo un'eredità di artigianalità e innovazione.

Più di 60 produttori qualificati ci guidano ad aumentare l’efficienza e a soddisfare le vostre esigenze di produzione.

I nostri processi ottimizzati e le nostre strutture avanzate ci consentono di soddisfare richieste di volumi elevati senza compromettere la qualità.

Abbi fiducia nel nostro track record di esportazioni di successo poiché continuiamo a contribuire a far crescere il successo delle aziende in tutto il mondo.

Rimaniamo impegnati nell'originalità e abbracciamo i design all'avanguardia che distinguono il tuo marchio dalla concorrenza.

Ogni prodotto subisce un meticoloso controllo per assicurarsi che soddisfi i nostri rigorosi standard prima di raggiungere le mani.

Approvvigionamento sostenibile e durevole per la tua attività ciclistica

SHINE SOON utilizza materiali leggeri e resistenti all'attrito per ridurre il carico di guida e ottenere la massima durata possibile.

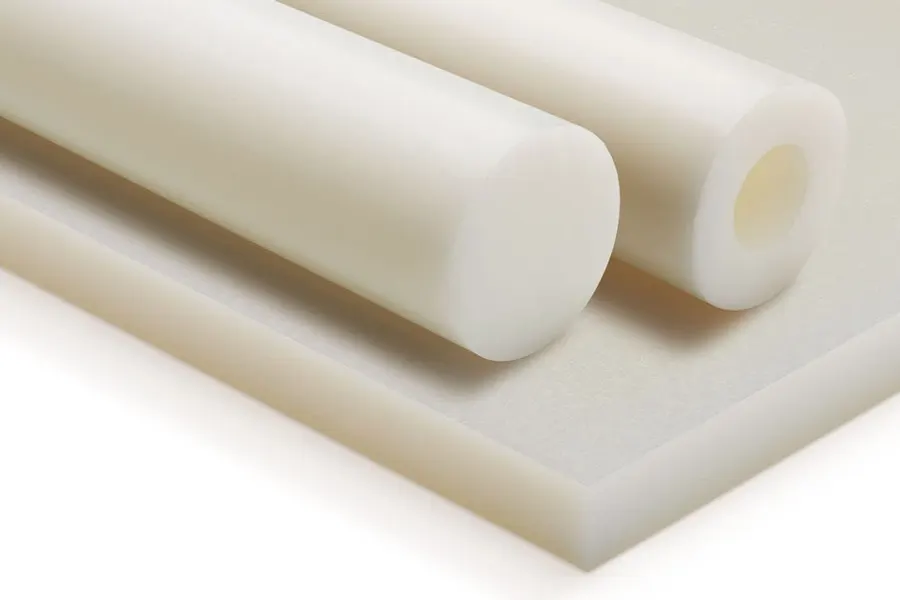

PA

Una resistenza alla trazione intorno 50-80 MPA lo rende adatto per parti di biciclette di lunga durata. Inoltre, Il PA è leggero, consentendo esperienze di guida agili ed efficienti.

Pp

La sua densità varia da 0.89 A 0.91 g/cm³, il risultato sono componenti leggeri per biciclette che migliorano la manovrabilità e un'eccellente resistenza alla fatica e agli urti.

Addominali

Una resistenza alla trazione di circa 40-60 MPa lo rende in grado di resistere a condizioni ciclistiche impegnative e facilita un'accelerazione più rapida e una migliore manovrabilità.

VERO

Una resistenza alla trazione che varia da 8 A 20 MPa fornisce eccellente elasticità e resistenza agli urti e garantisce una guida confortevole e protezione da urti e vibrazioni.

Lega di alluminio

Offre un rapporto resistenza/peso favorevole, con resistenze a trazione che vanno da 200 A 450 MPa. Sono comunemente utilizzati nei telai e nei componenti delle biciclette per la loro velocità e agilità.

Lega di titanio

Essi, come Ti-6Al-4V, offrono una resistenza alla trazione di circa 900-1000 MPa e sono utilizzati nei telai delle biciclette grazie al loro eccezionale rapporto resistenza/peso e alla resistenza alla corrosione.

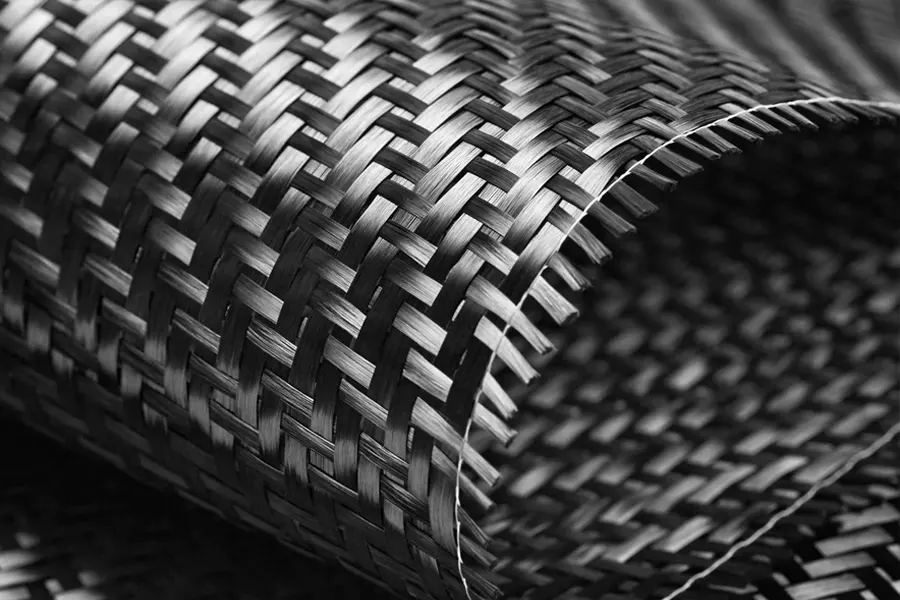

Fibra di carbonio

Ha un elevato rapporto resistenza-peso con resistenze alla trazione che raggiungono fino a 3,500 MPa. I suoi componenti forniscono un migliore trasferimento di potenza, smorzamento delle vibrazioni, e prestazioni complessive.

Vuoi più materie prime premium?

Contattaci e raccontaci di cosa hai bisogno, possiamo personalizzarne uno per te grazie a una catena di fornitura potente e stabile.

Parti MTB ergonomiche e progettate sul campo

Il nostro team di esperti produce abilmente ogni componente per migliorare la tua esperienza di guida, fornendo un comfort ottimale, maggiore efficienza, e un migliore controllo su terreni accidentati.

SHINE SOON si impegna a fornire design adatti, testati e perfezionati in condizioni reali. Abbraccia l'emozione di conquistare le montagne con la nostra alta qualità, parti per mountain bike appositamente costruite.

Approvvigionamento sostenibile e durevole per la tua attività ciclistica

SHINE SOON utilizza materiali leggeri e resistenti all'attrito per ridurre il carico di guida e ottenere la massima durata possibile.

Lavorazione dei metalli

La lavorazione dei metalli prevede la modellatura e la trasformazione dei materiali metallici per le parti di biciclette attraverso varie tecniche come il taglio, flessione, saldatura, e lavorazione.

Verniciatura a spruzzo automatica

Nel contesto della produzione di biciclette, la verniciatura a spruzzo automatica può essere utilizzata per applicare colori vivaci, rivestimenti protettivi, o elementi di branding sui componenti.

Stampaggio ad iniezione

Lo stampaggio a iniezione inietta materiali fusi in una cavità dello stampo per creare componenti in plastica per biciclette, come le cornici, manubrio, ingranaggi e così via.

Linea di pacchetti

La linea di confezionamento prevede lo smistamento, etichettatura, sigillatura, e parti e accessori di boxe per garantirne la protezione, organizzato, e pronto per la spedizione.

Non compromettiamo mai la qualità!

La gestione della qualità del prodotto e i test in bici consentono ai nostri pezzi di ricambio di superare le vostre aspettative e resistere alla prova del tempo.

Prova di tipo

Una resistenza alla trazione intorno 50-80 MPA lo rende adatto per parti di biciclette di lunga durata. Inoltre, Il PA è leggero, consentendo esperienze di guida agili ed efficienti.

Esperimento a temperatura costante

Assicurarsi che le parti della bicicletta abbiano una buona resistenza agli agenti atmosferici e siano adatte per le prestazioni di impazienza a caldo delle diverse regioni di utilizzo.

TEMP.programmabile&Camera HUMI

Assicurarsi che le parti e gli accessori della bicicletta abbiano prestazioni migliori di resistenza alla nebbia salina in condizioni difficili.

Test universale elettronico controllato da microcomputer

Valutare le proprietà meccaniche delle parti della bicicletta, come la resistenza alla trazione, forza di compressione, e resistenza alla flessione.

Prova a bassa temperatura

Assicurarsi che i componenti della bicicletta possano resistere e funzionare in modo efficace anche a temperature estremamente fredde.

Pompa manuale per test di pressione

I tecnici applicano e controllano manualmente la pressione per garantire che i componenti possano resistere ai livelli di pressione specificati.

Garanzia di certificazione

Come produttore di componenti per biciclette attento all'ambiente, SHINE SOON dà priorità all'uso di nuovo ed ecologico materiali nei processi produttivi. Aderiamo alle certificazioni leader del settore come RoHS, SGS, TÜV, BV, e ISO9001, garantendo ulteriormente la sicurezza e la sostenibilità dei nostri stabilimenti e dei nostri prodotti.

Il nostro impegno verso l'eccellenza è costante mentre ci sforziamo di fornire tecnologia e qualità esemplari a tutti i nostri stimati clienti.

RoHS

Privo di sostanze pericolose

PORTATA

Sicurezza in termini di uso chimico

Emarca

SGS, Certificato TUV e BV

GS

Conformità allo standard tedesco

Ce

Conformità alla salute, sicurezza, e tutela dell'ambiente

ISO9001

Aderenza agli standard di gestione della qualità

Pronto a elevare le prestazioni della tua bici a nuovi livelli?

Unisciti a noi per prepararti a pedalare con potenza, precisione, ed eleganza mentre sveliamo la nostra straordinaria gamma di robuste parti per bici.