Les pièces de vélo sont très importantes car elles ont un impact direct sur la qualité, sûr, et confortable, votre conduite est. Bons freins, engrenages, et les cadres assurent le bon fonctionnement de votre vélo, arrêter de manière fiable, et éviter de tomber en panne, ce qui signifie plus de plaisir et moins de tracas pour vous. Cependant, ce qui définit vraiment une pièce de vélo de qualité supérieure? C'est une combinaison de matériaux haut de gamme, artisanat, et des tests rigoureux. Vérifions-le maintenant!

À BRILLER BIENTÔT, nous utilisons des années d'expérience et des équipements de pointe pour garantir que chaque pièce de vélo que nous fabriquons est de premier ordre. Avant d'acheter, nous vous encourageons à consulter nos matériaux soigneusement sélectionnés et nos contrôles de qualité. Découvrez maintenant comment nous établissons la norme en matière de production de pièces de vélo..

Quel matériau prend la partie vélo?

SHINE SOON utilise des matériaux légers et résistants au frottement pour réduire la charge de conduite et obtenir la plus longue durée de vie possible. Voici un bref aperçu des matériaux couramment utilisés.

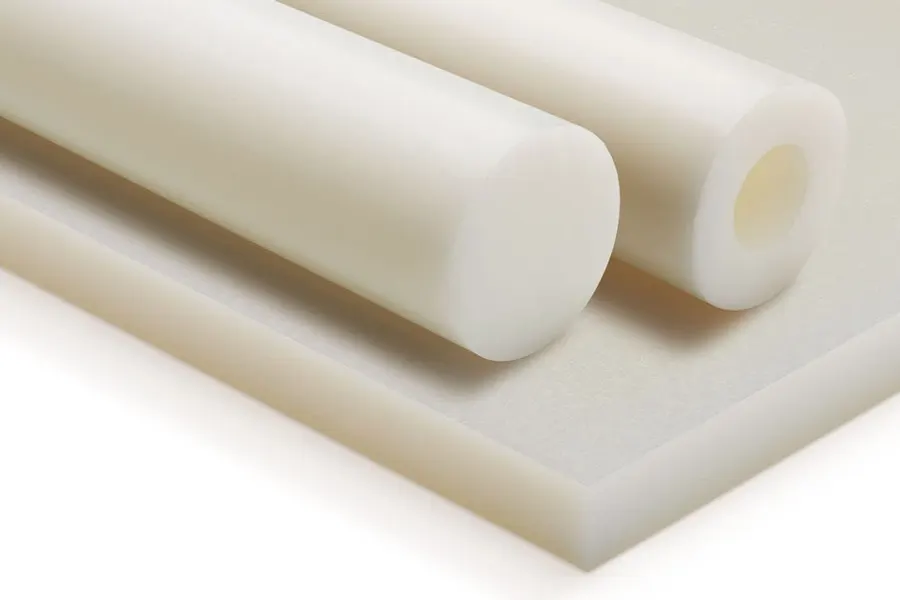

1. Pennsylvanie (Polyamide):

Description: Un plastique résistant connu pour être solide et durable.

Utilisations: Vous le trouverez dans pédales de vélo, boîtiers de dérailleur, et d'autres parties qui doivent supporter beaucoup de stress.

Spécifications de SHINE SOON: Une résistance à la traction d'environ 50-80 MPA le rend adapté aux pièces de vélo durables.

2. PP (polypropylène):

Description: Un plastique léger qui résiste aux produits chimiques et à l'usure.

Utilisations: Ce matériau est souvent utilisé dans les ailes de vélo, porte-bouteilles de vélo, et des poignées : des pièces qui n'ont pas besoin d'être très résistantes.

Spécifications de SHINE SOON: Sa densité varie de 0.89 à 0.91 g / cm³, ce qui donne des composants de vélo légers.

3. Abs (Acrylonitrile Butadiène Styrène):

Description: Un fort, plastique résistant aux chocs.

Utilisations: C'est courant dans casques de vélo et certaines pièces du cadre qui doivent absorber les impacts.

Spécifications de SHINE SOON: Une résistance à la traction d'environ 40 à 60 MPa avec la capacité de résister à des conditions de cyclage exigeantes

4. Tru (Caoutchouc thermoplastique):

Description: Un matériau flexible qui combine le meilleur du caoutchouc et du plastique.

Utilisations: Parfait pour poignées de vélo, bandes de guidon, et les pièces qui doivent absorber les vibrations.

Spécifications de SHINE SOON: Une résistance à la traction allant de 8 à 20 MPa offre une excellente élasticité et résistance aux chocs.

5. Alliage d'aluminium:

Description: Un mélange d'aluminium et d'autres métaux pour le rendre plus solide.

Utilisations: Vous le verrez dans les cadres de vélo, guidon, jantes, et tiges de selle. C'est léger et solide.

Spécifications de SHINE SOON: Un rapport résistance/poids favorable, avec des forces de traction allant de 200 à 450 MPA.

6. Alliage en titane:

Description: Un alliage à base de titane, connu pour être super solide et léger.

Utilisations: Cadres de vélo haut de gamme, tiges de selle, et les pièces où vous avez besoin à la fois de résistance et de légèreté.

Spécifications de SHINE SOON: Utilisez du i-6Al-4V avec une résistance à la traction d'environ 900-1000 MPa avec un rapport résistance/poids et une résistance à la corrosion exceptionnels.

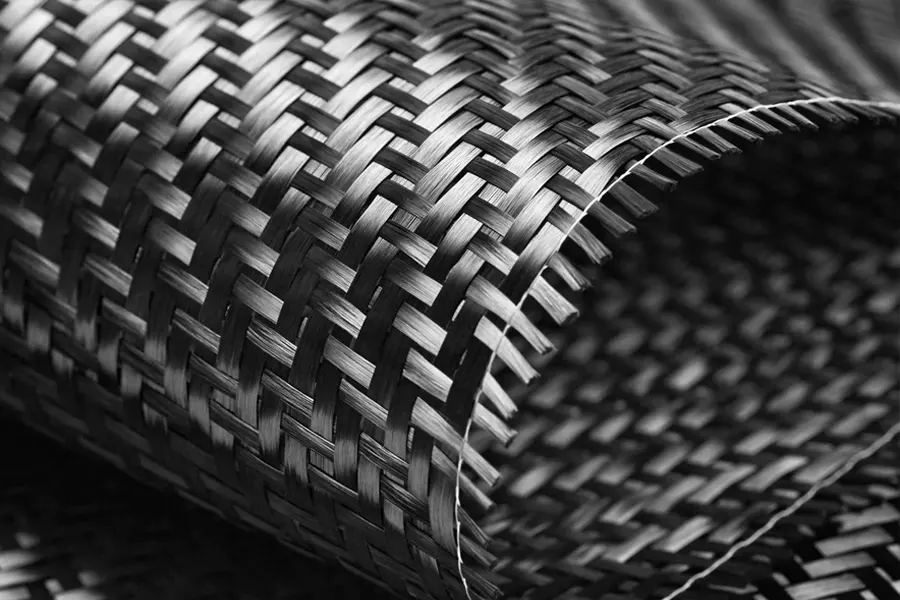

7. Fibre de carbone:

Description: Un matériau fabriqué à partir de fibres de carbone tissées en tissu et serties de résine.

Utilisations: Trouvé dans les cadres de vélo haute performance, fourchettes, et roues parce que c'est vraiment solide et super léger.

Spécifications de SHINE SOON: Un rapport résistance/poids élevé avec des résistances à la traction allant jusqu'à 3,500 MPA, offrant un transfert de puissance amélioré, amortissement des vibrations, et les performances globales.

Autres matériaux dans les pièces de vélo:

Acier: Un choix classique pour les cadres et composants de vélo, surtout sur les vélos bas de gamme. C'est solide et abordable.

Alliage de magnésium: Utilisé pour les pièces légères comme les roues ou les cadres sur certains vélos haut de gamme. C'est léger et solide.

Caoutchouc: Présent dans les pneus et les poignées pour fournir traction et amorti.

Céramique: Utilisé dans les roulements de vélo haut de gamme. Il est durable et réduit la friction pour des déplacements plus fluides.

Acier inoxydable: Utilisé pour les câbles et fixations de vélo car il ne rouille pas et est vraiment solide.

Différents matériaux sont choisis en fonction de leur résistance, poids, et le coût qu'ils doivent équilibrer pour chaque pièce de vélo.

Contrôle qualité dans la partie vélo

Le contrôle qualité des pièces de vélo consiste à garantir la fiabilité de chaque composant., sûr, et fonctionne bien. Voici comment cela fonctionne généralement dans SHINE SOON:

Test de type

La résistance à la traction mesure la force qu'un matériau peut supporter avant de se briser. Pour les pièces de vélo, une force de 50-80 MPa signifie qu'ils peuvent durer longtemps sans se casser. Aussi, Pennsylvanie (Polyamide) est vraiment léger, rendre les vélos plus faciles à conduire et à contrôler. Les matériaux légers rendent le vélo plus rapide et plus agile.

Expérience à température constante

Cette expérience vérifie si les pièces du vélo peuvent supporter différentes températures. En soumettant les pièces à des conditions chaudes et froides, nous garantissons qu'ils ne seront pas endommagés. Ce test garantit que le vélo fonctionne bien, peu importe où vous le conduisez.

Chambre programmable TEMP HUMID

La chambre TEMP HUMID teste la façon dont les pièces de vélo résistent aux conditions salées et humides. Ceci est crucial pour les endroits proches de l'océan où le sel peut provoquer de la rouille.. En simulant différents climats, on peut voir si les pièces dureront longtemps, même dans des environnements difficiles.

Test universel électronique contrôlé par micro-ordinateur

Ce test utilise un ordinateur pour vérifier la résistance des pièces du vélo. Il mesure à quel point ils s'étirent, compresse, et plier. Les données détaillées de ce test nous aident à savoir si les pièces sont solides et sûres pour la conduite..

Test à basse température

Ce test vérifie si les pièces du vélo peuvent encore fonctionner même lorsqu'il fait très froid. Si vous mettez les pièces à des températures glaciales, ils ne s'affaiblissent pas et ne se brisent pas, ce qui veut dire que les pièces du vélo sont bonnes. Cela garantit que votre vélo fonctionnera bien même en hiver.

Pompe de test de pression manuelle

Les techniciens utilisent cette pompe pour appliquer manuellement une pression sur les pièces du vélo comme les freins et la suspension.. En contrôlant la pression, nous nous assurons que les pièces peuvent supporter le stress auquel elles seront confrontées lorsque vous roulez.

Ces tests permettent de garantir la solidité des pièces de vélo, fiable, et prêt pour toutes les conditions de conduite, pour vous garder en sécurité et votre vélo en pleine forme.

Connaissez votre fabricant et votre fournisseur, BRILLER BIENTÔT

La meilleure façon de vous assurer que vous recevez des pièces de vélo de haute qualité est de connaître le fabricant et fournisseur de pièces de vélo. Il existe une douzaine d'entreprises manufacturières qui peuvent répondre à vos besoins flexibles., mais seuls quelques-uns ont l'expertise nécessaire pour vous fournir des pièces de vélo de haute qualité. SHINE SOON est une entreprise experte dans la fabrication de pièces de vélo.

Situé à Zhejiang, l'usine a 30 000㎡, démontrer l'excellence de la fabrication en Chine. Nous offrons un héritage de savoir-faire et d’innovation.

Plus que 60 Les producteurs qualifiés nous amènent à accroître l'efficacité et à faire conclure vos besoins de fabrication.

Notre rendement mensuel est 70,000+. Nos processus rationalisés et nos installations avancées nous permettent de répondre aux demandes de haut volume sans compromettre la qualité.

Portée annuelle des exportations $8,000,000+. Faites confiance à notre expérience en matière d’exportations réussies, alors que nous continuons à contribuer au succès des entreprises du monde entier.

Nous avons 10+ Designs originaux annuels, montrant que nous restons attachés à l'originalité et adoptons les designs d'avant-garde qui distinguent votre marque de la concurrence..

Chaque produit subit un examen minutieux pour s'assurer qu'il répond à nos normes strictes avant d'atteindre vos mains.

Contactez SHINE BIENTÔT maintenant pour améliorer votre expérience cycliste!